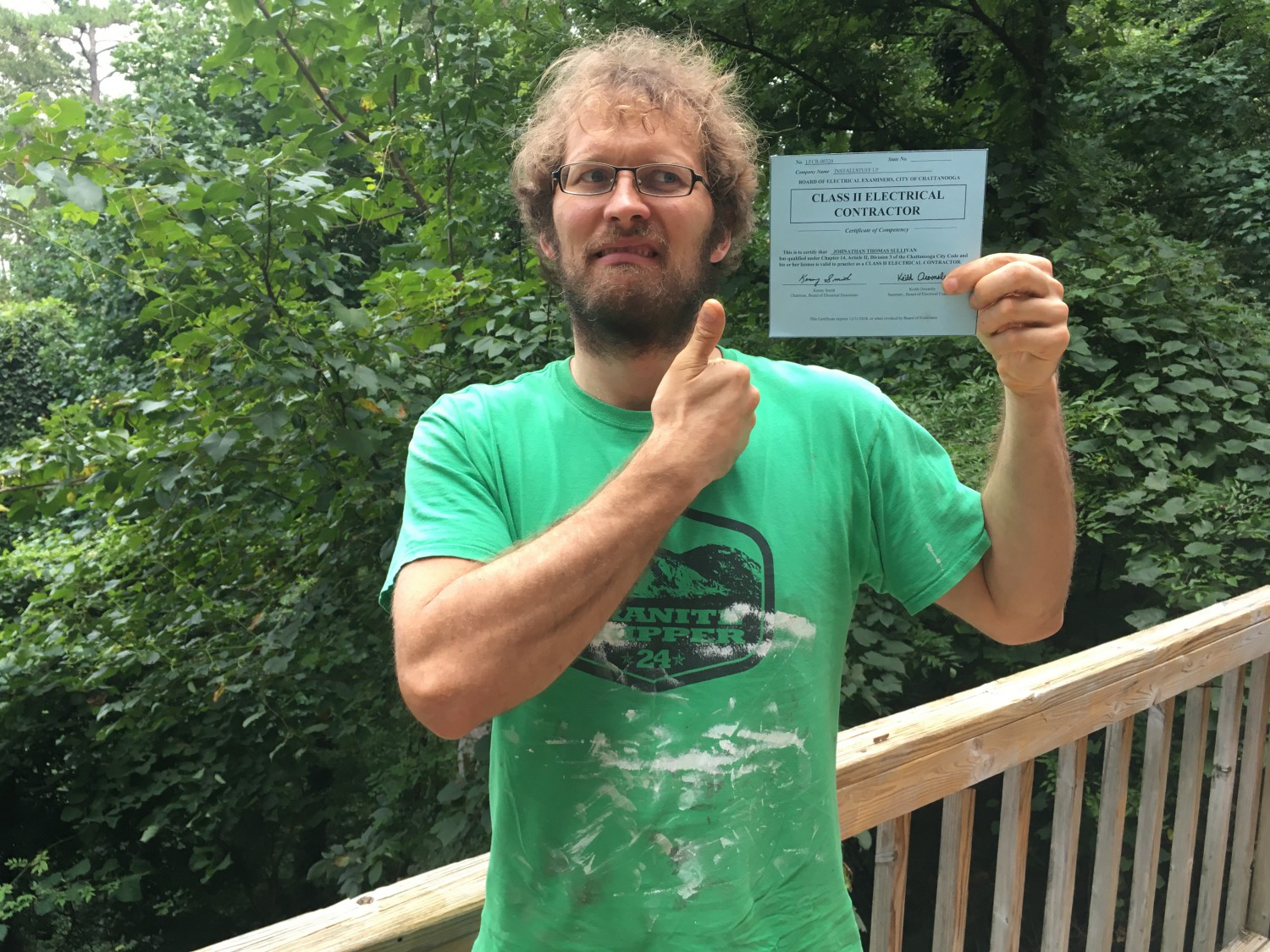

Somehow, the city of Chattanooga believes that obtaining an Electrical Engineering degree is akin to performing 15,000 hours of work as an electrician*. As someone with an EE degree, I can confirm that this is definitely not the case. In fact, most of the details in the rest of this post are ones that had to be transcribed word for word from things John told me, because my understanding of wiring a house is next to nil. Fortunately for everyone, I was not the only one with an EE degree; John has far more knowledge and experience in that area than I do and can now add “Licensed Master Electrician” to his list of job titles.

*To clarify, electrical work is one of the areas that require a licensed professional to pull a permit and to do the work. If you have an Electrical Engineering degree from an accredited university, you can take a test and become a master electrician in Chattanooga. Normally, this test is not available to anyone until they have had a master electrician sign off on at least 15,000 hours of work.*

As with all other areas of our house, we went overboard in the electrical department. In what will be a recurring theme, we again made a lot of decisions based on things we hate in our current house. For example:

- In the house we live in now, the front porch light is controlled from a switch in the dead center of the house. Going from the front door to our bedroom requires backtracking three times to turn off lights as you go (or groping around in the dark). So in our new house, our stairs have a six way switch and can be turned on or off at basically every possible place. We also have more than 20 three and four way switches throughout the house.

- John’s current office has a single outlet with five daisy chained power strips. So he made sure that his new workspaces would have lots of outlets. His office and the garage each have three dedicated circuits with more than 15 plugs.

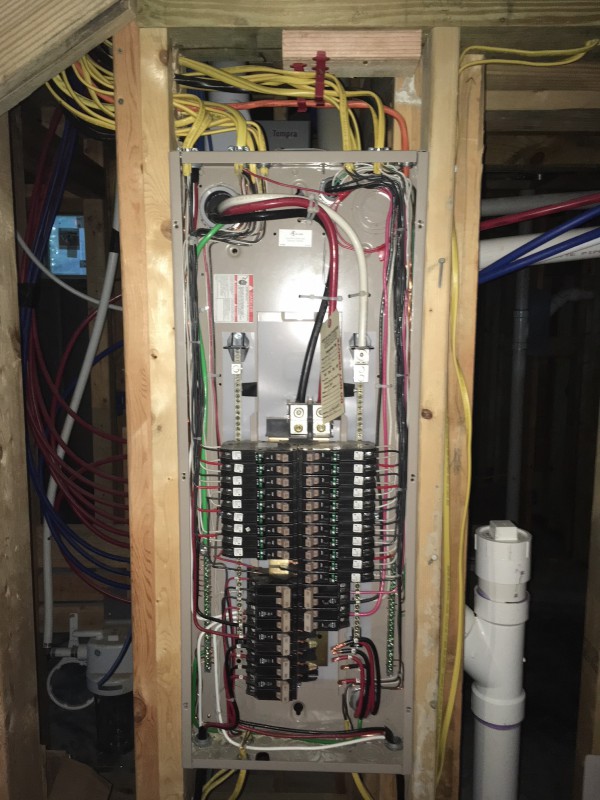

- We used a 40 gang branch circuit panel that is totally full. Our hot water heater uses six breakers, our heating and cooling system uses another four, the dryer, stove, and car chargers (for cars we don’t own) each use two, and the rest are distributed among lights and outlets.

- We used over 3,000 feet of Romex wire.

- Our kitchen alone has eleven different circuits: Three on the island, two on the counter, two for the stove, one for the lights, one for all the outlets, one for the fridge, and one for the microwave.

- We wired the entire house with 12 gauge wire and 20 Amp breakers.

- We put in 75 recessed lights. Lowe’s was having a huge sale on the exact light we wanted, so I bought their entire stock. John went back a week later to see if they had gotten any more, but was told that “some lady came and bought them all”.

We have 17 recessed lights in our living room alone (on three different switches). You can also see that we used a combination of wood, foam, and caulk to air seal the space around each fixture.

Unfortunately, we failed our first inspection spectacularly. There were certainly some code violations that we simply weren’t aware of, but we also think the inspector’s attitude played a big part. He was already grumpy for having to fill in for someone else that day and I doubt this early interaction helped:

Inspector: “How did you not learn to do this properly as a journeyman?”

John: “Oh. I was never a journeyman. I just took a test and now I’m a licensed master electrician.”

Every time he walked into a new room, he would sigh dramatically and start listing off all the problems. By the end, John ran out letters in the alphabet to label the code violations. While many of them were reasonable things that needed to be fixed, there were some that seemed a bit nit-picky and a pain to fix:

- Our living room is alongside the main staircase, so one side will have a railing instead of a wall. Apparently the railing actually counts as a wall for code compliance, and therefore we were required to add two floor outlets along the edge. Each one cost 100 times more than a standard outlet, they look terrible, and they require us to cut through the floor and add wiring underneath.

- According to the manual, each of our indoor A/C units specifically call for an 18/4 wire. Despite this, the inspector insisted that we run 14/2. Since it’s too large to fit in the junction terminals, we ended up having to run two separate wires.

- He insisted that the kitchen could only have one pantry and that the ‘storage closet’ must be on a separate circuit from the kitchen (and apparently the fact that the kitchen already had 11 circuits didn’t mean one could be multi-purposed).

- Wires must stapled in the center of walls within twelve inches of every light and outlet. There were a few times where we stapled two wires sideways next to each other instead of flat on top of each other (resulting in the exact same size and positioning). Additionally, a 2×4 wasn’t considered wide enough to staple wires next to each other, so we had to get wire bridges to stack them.

- We had numerous boxes that were slightly over capacity. And by slightly I mean by .25 cubic inches or about 1% of the total capacity. He insisted that there wasn’t a residential box capable of handling them and that we would have to do a lot of rerouting. Fortunately, such a box did exist and we upgraded all of them.

- Apparently there is a rule that wires running vertically through insulation must be separated into groups of three or four (but for some reason does not apply to wires running horizontally). Our circuit panel is located in the garage – which needs to be insulated – so we had about 24 wires running through the wall in one group.

The inspector’s word is god, so we tucked our tails, made adjustments, and passed our electrical inspection.

Thanks for the interesting / informative post regarding the electrical inspection. I’m sure it was a good choice to say “yes sir” and make the required changes. I especially liked the ingenious way you complied with the three wire max through vertical studs. (I’m not sure I understand “why” that’s a rule.) Congratulations on becoming a Licensed Master Electrician too!!

Thanks again for the update.

Tom

Yes, congratulations on your new title. I like your response to the inspector.

just wait until he completely changes his mind, either because he learns he was wrong or forgot, or something more malicious, or he gets a new job and his backfill disagrees (I’ve experienced most of that at some point).