We tend to make design decisions based on things we hate about the old house we are currently renting. One of our primary gripes is the water pressure. If someone is doing a load of laundry, the shower is reduced to a trickle. If you flush a toilet, it takes about a minute to fill a single glass of water from the sink. If you use cold water while someone is showering, they get blasted with scalding water.

As a result, we may have gone over the top in terms of designing the water system in our new house:

- 28,800 Watt tankless water heater:

- For comparison, an average stove only pulls about 9,000 Watts

- If it were any larger, it would require an industrial boiler permit (required at 29,000 Watts)

- Will heat 4.5 gallons of water per minute to 110 degF, which is enough to run a shower, dishwasher, and washing machine at the same time with no discernible changes

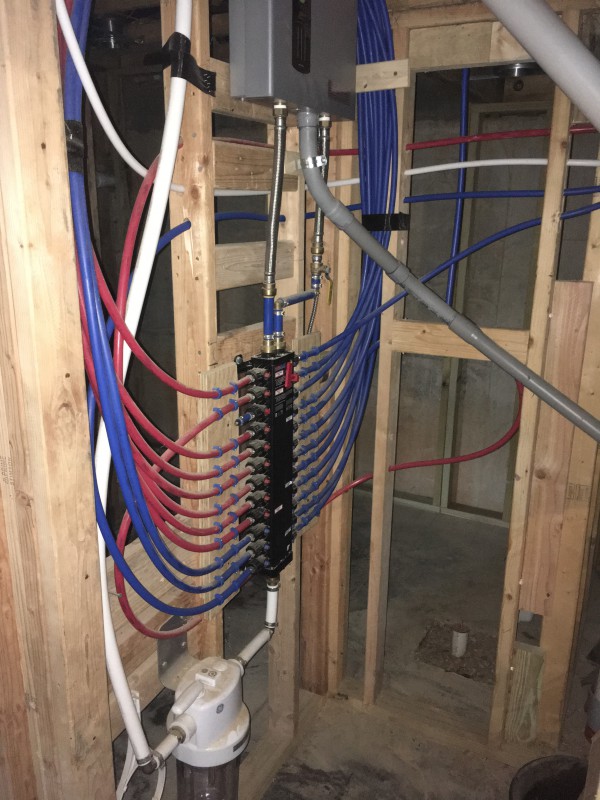

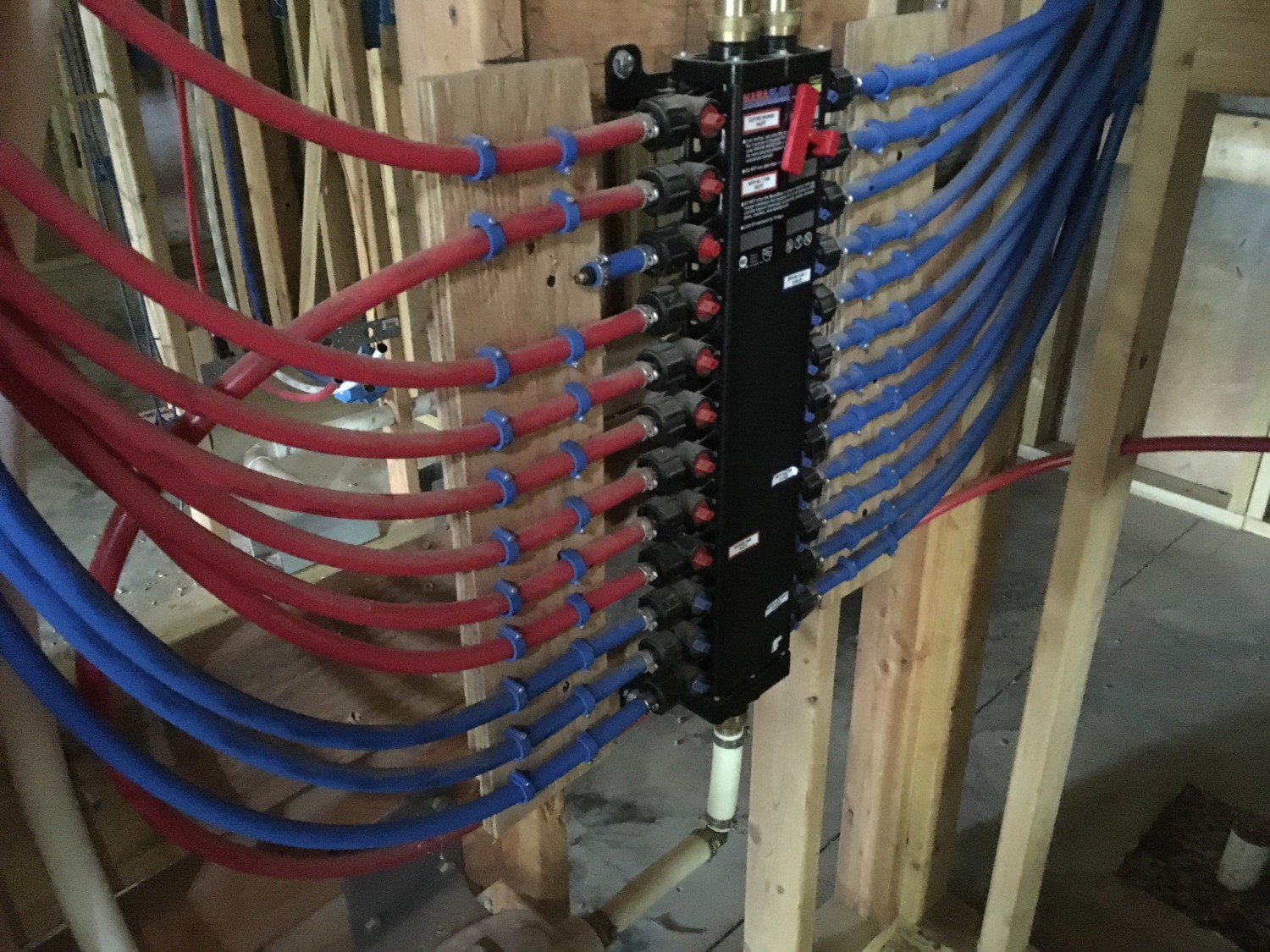

- Pex distribution manifold:

- Most homes have a main trunk line that moves through all the fixtures one-by-one, so they are all sharing the water in that single line. The Pex distribution manifold, on the other hand, sends a separate line to every fixture. This way, the only limiting factor is the rate at which water is delivered to our house.

- Whole house filtration system

- Dedicated Nalgene filler:

-

Our fridge currently takes about 45 seconds to fill a Nalgene. Considering the number of water bottles we fill each day, it has become a nuisance. So John hooked up a dedicated water line in the island specifically for a fixture that can fill a Nalgene in 7 seconds. Being who is, he has instructed me to say that it will save him 11.5 hours per year, or 14 dys over 30 years. John has decided he will use this saved time to geek about about all the time he is saving. Although he notes that most of the geeking out will occur in 7 second intervals while he is actually filling water bottles.

The base of operations for our house’s water. At the top is the tankless water heater, the middle is the Pex distribution manifold, and the filtration system is shown in the bottom.

We had to take a corner out of the master closet in order to route sewage pipes and HVAC lines. One thing we didn’t think about when designing our house was stacking walls over one another, so many of our lines have to take round-about paths to get between floors.

In preparation for the inspection, John figured he could take a 30 minute break from some exhausting labor and fill the pipes to confirm that there were no leaks. Despite the fact that the sewer lines are not a pressurized system, the system must be completely full. In our case that meant 30 feet of water or roughly 13 PSI.

On the first attempt, the caps that John used to plug the openings came loose multiple times, creating massive geysers of water inside our house and soaking everything in the near vicinity. He eventually manually reinforced the plugs (which were specifically rated to handle 30 feet of pressure) and discovered a number of small leaks. Unfortunately, a leak cannot simply be plugged or re-glued; each leaky joint must be completely redone, often requiring a number of pieces to be cut out and a puzzle to figure out how to insert a new piece into the existing joints. What he had expected to be a 30 minute break turned into a multi-day challenge.

But, the important thing is that we passed our rough-in plumbing inspection on the first go!

Leave a Reply